经向切割机

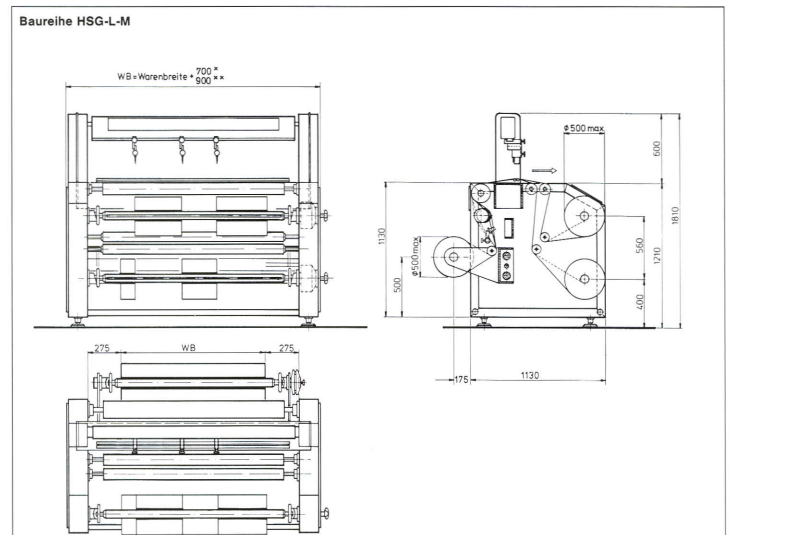

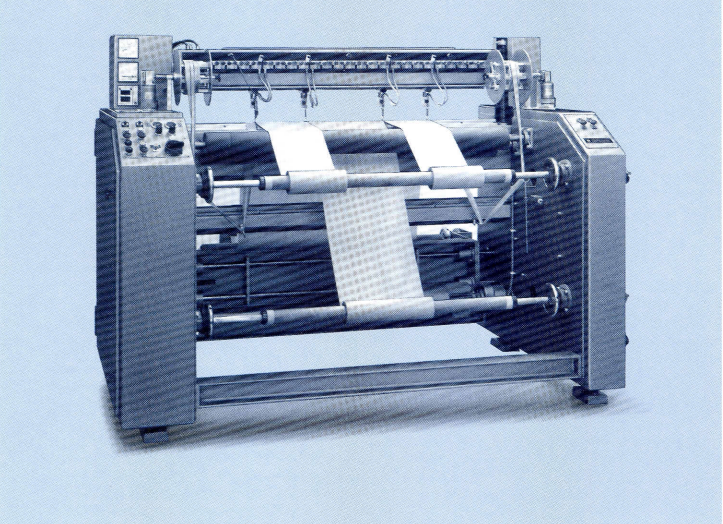

The heat cutting machine model HSG-L-M operates from roll to roll. A rubber coated conveyor roll pulls the fabric from the bale, the cloth then moves on to a ceramic cutting base (ceramic tubes) is separated by a hot blade and is immediately expanded after the separation by 2 motor driven rubber rollers to avoid refusing of the separated edges. The separated material is then rolled on 2 friction shafts

经向切割机HSG-L-M是以卷到卷的方式运行的。一个有橡胶包裹的运输滚筒把要加工的布料从捆状中拉出来,然后将布料传送到陶瓷切割底座上(陶瓷管)。布料会被一个热刀分割开并在被切割开后立即被两个发动机驱动的橡胶滚筒分别拉向两个方向。被分离的材料最后会在两个摩擦轴上被卷起来。

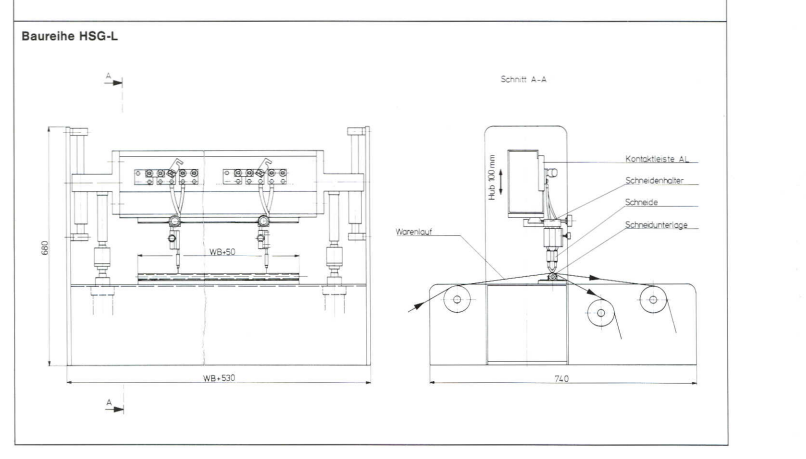

The blades rest on the cutting base with a spring-type system. They are mounted (together with the blade holders) to a crossbeam which can be lowered or lifted by either electric or pneumatic power. As soon as the fabric flow or machine movement is interrupted, the crossbeam is lifted. This prevents a burning of the fabric edge since the blades are automatically removed from the fabric also. To continue the cutting operation the blades are lowered first, before the material begins to move onwards. This ensures that no interruption of the cutting process will be noticed on the material. The machine is also fitted with a contact rail with numerous contact pieces which allow connection/positioning of the individual cutters at any position/distance.

刀片放在一个带有弹簧式系统的切割底座上,它们和刀片固定器一起被安装在一个可以通过电动或气动升降的横梁上。一旦机器运作被打断,横梁就会抬起,刀片会随着横梁的抬起从布料上移开,这就能防止切割边缘因与刀片长时间接触而被烧毁。在继续切割操作之前,刀片会先降低到切割的位置,然后布料才会开始移动,这样切割好的布料上就不会看出有中断的痕迹。这台机器还带有一个有许多的接触片接触轨,这使得它可以在任何位置上放置单独的切割器。

In case of necessity an edge-controlling unit (accessory part) can be fitted to the machine. If the layers on the fabric bale are not rolled accurately (slipping of the layers), the edge control unit corrects the fabric flow to receive a straight cut along the warp thread.

在必要时,可以将边缘控制单元(附件部分)安装在机器上。如果面料不能被精确地卷成一捆,边缘控制单元就会纠正面料的流动来确保切割能够笔直地沿着经线进行。